Designing and building radiation shielding can pose a variety of challenges, such as limitations on space, price, weight, and installation. One of the most versatile forms of shielding material that is used to overcome these challenges is lead—it’s less expensive, readily available, and easy to process into finished radiation shielding products. Lead is used in the construction, nuclear power, non-destructive testing, academic, and medical fields for radiation protection and shielding.

Designing and building radiation shielding can pose a variety of challenges, such as limitations on space, price, weight, and installation. One of the most versatile forms of shielding material that is used to overcome these challenges is lead—it’s less expensive, readily available, and easy to process into finished radiation shielding products. Lead is used in the construction, nuclear power, non-destructive testing, academic, and medical fields for radiation protection and shielding.

Material Properties

Lead is a soft metal that can be easily scratched or dented. Being ductile and malleable makes lead very easy to work with. It is a very dense metal with a density of 11.34 g/cc, approximately 4 times the density of aluminum. Lead has a melting point of 327oC which makes it an ideal metal to cast.

There are many different alloys and purities of lead available. One of the most common is ASTM B-29 lead, which has a minimum purity of 99.94% lead. The lead is refined to reach this level of purity. Antimony is a common metal alloyed with lead to increase hardness and mechanical strength. Antimonial lead typically has an antimony concentration of 1-6%.

Properties of Lead

| Melting Point | 327.5oC (621.5oF) |

| Density (Room Temperature) | 11.34 g/cc (0.410 lb./in3) |

| Atomic Number | 82 |

| Stable Isotopes | 204Pb, 206Pb, 207Pb, 208Pb |

Lead is toxic and can accumulate within the body if proper precautions are not taken. Encapsulating the lead in metal, plastic, or paint will greatly reduce the risk of lead exposure.

Lead Attenuation

Lead is very effective at shielding gamma radiation. Because of the density of lead, its high atomic number, and stable isotopes, lead is ideal for stopping gamma and x-ray radiation. For a gamma ray from a Colbalt-60 source, pure lead has a Half-Value Layer (HVL – the thickness of shielding required to reduce the level of radiation by 50%) of approximately 12.5 mm (0.49 in). A lead shield will be thinner than a steel (21.6 HVL) or concrete (60.5 HVL) shield of the same effectiveness in shielding a Co60 source. From an x-ray source with a peak voltage of 200 kV, the HVL of lead would be 0.52 mm (0.021 in).

Lead Processing

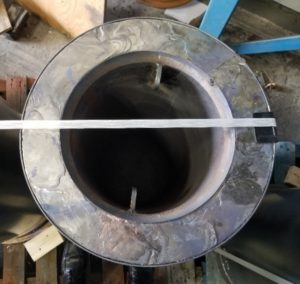

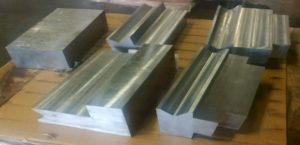

Typically lead can come in several different forms. It is common to melt the lead and either cast it in a mold or fill a pre-made fabrication. Lead bricks are an example of a cast lead product. The molten lead is poured into a preheated mold and as the lead cools, the lead shrinks and the casting can be removed from the mold. Lead can also be machined to achieve tighter tolerance than would be possible with just a casting. Typically, alloys of lead, such as 2-4% antimonial lead, are easier to machine because the antimony makes the lead harder and less prone to chipping when cut.

Extruding and rolling lead is possible because lead is very malleable. Sheet lead is formed from rolling lead, and is a very useful product for shielding. In x-ray or gamma testing applications, sheets of lead can be easily installed in barriers, walls, and mounted on drywall and plywood. Lead can come as thin as 1/32”, making it easy to bend and fold around walls. The most common thicknesses of sheet lead used are 1/32”, 1/16”, 1/8”, and ¼”.

Lead has many uses for radiation protection, from creating lead-lined furniture to small lead vials. Because of its availability, price, and the ability to

form, cast, or machine, lead can be made into any radiation shielding product that you could want. If you would like to find out more information about lead fabrication and shielding, visit the MarShield website or contact MarShield directly, and we will help you find the best radiation shielding solution for your needs.